Your wage bill keeps creeping up, but your team is already stretched. Sound familiar?

Between National Living Wage rises, higher NI, delivery platforms taking a cut, and last-minute rota changes, many UK restaurants are sitting at 30%+ labour cost… while profit sits near zero. Cutting shifts feels risky. Cutting staff feels impossible.

This guide shows you how to trim 5–10% of labour cost by attacking wasted hours, not people. You’ll learn how to: calculate your true labour cost, use the data you already have, forecast demand, build smarter rotas, and keep your team onside while you do it.

What does a “healthy” labour cost look like for UK restaurants?

Most restaurants aim for a restaurant labour cost percentage somewhere in the 25–30% of sales range, depending on concept and service style. Industry benchmarks for full-service operations often sit closer to 30–35%, especially where service is more labour intensive.

In simple terms, labour cost percentage = (total labour costs ÷ total sales) × 100.

If your monthly labour cost is £8,000 and your sales are £25,000, your labour cost percentage is:

-

£8,000 ÷ £25,000 × 100 = 32%

That 2–7 percentage point gap between a “lean” 25–30% and a real-world 32%+ is exactly where many UK restaurant labour costs now sit – and it is eating what is left of your profit. Rising wage bills across hospitality and lower overall profitability in UK companies make that gap harder to

Quick check – is your labour cost healthy?

Under 25%: check you are not understaffed or underpaying

25–30%: usually healthy, depending on concept

30–35%: watch closely and look for wasted hours

35%+: urgent review needed

💡If you want to see your labour cost percentage live while you build the rota, Shiftbase lets you add expected turnover to the schedule and compare wage costs with sales in real time.

-

Most operators are not “bad with numbers”. Your restaurant labour costs in the UK are creeping up because the whole system around you has shifted. A few big drivers:

-

Wage hikes – The National Living Wage jumped by 9.8% in April 2024 and minimum wages for younger workers rose even faster, pushing up base pay across

-

Higher employer NI – Changes to employer national insurance contributions are adding around £1bn in extra costs for hospitality, hitting labour-heavy businesses hardest.

-

Turnover and shortages – UK hospitality sees some of the highest staff turnover, often 30–40%+ a year, meaning constant recruitment, training, and lost productivity.

-

Demand swings – Wet Tuesdays, rail strikes, bank holidays and events make demand volatile, so you either overstaff “just in case” or risk service failures.

-

Hidden admin time – Paper timesheets, manual rota edits, and chasing availability quietly add unpaid manager hours into your true hospitality labour cost.

-

-

When margins are tight, it is tempting to shave hours off the rota or leave a vacancy unfilled. The problem: a labour cost that is too low can hurt you more than a labour cost that is slightly high.

Here are 3 ways cutting staff costs you more later:

- Service drops, reviews follow

With one server down, tables wait longer, upsell drops, and reviews suffer. Lower sales per labour hour undo any short-term “saving”. - Burnout and higher turnover

Remaining staff absorb the workload, pick up more doubles, and burn out. Hospitality already faces some of the highest churn in the UK; pushing harder accelerates exits and piles on recruitment and training costs. - Inconsistent standards and training gaps

When you run minimal headcount, there is no slack for proper onboarding, cross-training, or coaching. You end up with more mistakes, more comped meals, and more management fire-fighting.

- Service drops, reviews follow

Let's dive into the process of cutting down labour costs in your restaurant, without sacrificing your staff.

Step 1 – Get a clear baseline of your labour costs

Before you tweak rotas or shift patterns, you need a cold, honest view of what your labour actually costs today.

How to calculate your restaurant labour cost percentage

To calculate restaurant labour cost percentage, you only need two numbers that cover the same period: total labour costs and total sales.

Use this simple process:

- Choose a period

Pick a typical week or month (avoid big events that distort the picture). - Add up your total labour costs

Include: wages, salaries, employer NI, pension contributions, holiday pay, and other payroll on-costs. Benchmarks and calculators usually recommend including all these costs so your restaurant labour costs UK picture is accurate. - Add up your total sales

Use gross sales from your POS or accounting system for the same period. - Apply the formula

Labour cost % = (total labour costs ÷ total sales) × 100

Example for a UK restaurant:

| Metric | Amount |

|---|---|

| Total labour costs | £8,000 |

| Total sales | £25,000 |

| Labour cost % | 32% |

So if your labour cost is £8,000 and your sales are £25,000:

£8,000 ÷ £25,000 × 100 = 32% restaurant labour cost percentage.

Break labour down by role, day and channel

A single percentage hides where the real problems are. To cut labour costs by 5–10%, you need to see who is costing what, and when.

Break labour into three views:

-

By role – front of house, back of house, management, bar, delivery.

-

By day and daypart – weekday vs weekend, lunch vs dinner, pre-theatre vs late.

-

By channel – dine-in, takeaway, delivery, events.

A simple weekly view might look like this:

| Day | Labour cost | Sales | Labour % | Notes |

|---|---|---|---|---|

| Monday | £900 | £2,400 | 37.5% | Quiet lunch, overstaffed |

| Friday | £1,600 | £6,000 | 26.7% | Strong dinner trade |

| Sunday | £1,300 | £3,000 | 43.3% | Too many FOH on brunch |

Do the same by role (e.g. FOH vs BOH) and, if you run delivery, split out the labour behind that channel. This is usually where you find overtime, duplicate cover or “just-in-case” shifts. Industry guidance on restaurant analytics shows that combining POS sales with staffing data makes it much easier to see where labour is misaligned with demand.

Set a realistic 5–10% saving target (without breaking the law)

Now you know your current numbers, it is time to choose a target – without cutting staff and without breaking UK labour laws.

Work through it step by step:

- Find your starting point

Let’s say your current restaurant labour cost percentage is 32%. - Choose a realistic target

Aim for 29% over the next 12 weeks – that’s roughly a 10% reduction in cost relative to sales, which is tough but achievable if you focus on wasted hours, not headcount. - Translate this into weekly goals

Decide how much labour cost you need to shave off per week (e.g. £250–£300) through better scheduling, less overtime and tighter admin. - Check legal guardrails

- Respect National Minimum and Living Wage for every age group.

- Follow Working Time Regulations for rest breaks and maximum weekly hours – staff working over six hours must get at least a 20-minute uninterrupted break, and they’re entitled to daily and weekly rest.

If your labour % drops because people are skipping breaks or being underpaid, that is not a win – it is a risk. The goal is fewer wasted hours, not fewer people.

Step 2 – Connect the data you already have

You probably own more useful data than you think – it is just scattered across systems and spreadsheets.

What data do you need for data-driven scheduling?

For proper data-driven scheduling, you need to see staffing and demand on the same page. For most UK restaurants, that means pulling together:

-

Sales data – from your POS, ideally by 15 or 30 minutes.

-

Bookings data – covers and times from your reservation system.

-

Online orders and delivery data – volumes and peaks by channel.

-

Weather data – hot days, rain and storms change walk-in patterns.

-

Events data – local events, sports, school holidays, payday weekends.

-

Promotions data – vouchers, set menus, campaigns that drive spikes.

Step 3 – Build a simple demand forecast

You do not need AI to start forecasting demand, but you do need a consistent way to predict how busy you will be.

Spotting patterns in your sales and covers

Restaurant demand forecasting means using historic sales, covers and external factors to predict how busy you will be on a given day or hour, so you can staff accordingly.

Start with the basics:

-

Compare Mondays vs Fridays – often Fridays are 30–40% busier.

-

Look at payday weekends, school holidays and big local events.

-

Check how weather affects your terrace, walk-ins or delivery mix.

Turning those patterns into demand “levels”

To make your forecast usable in day-to-day scheduling, turn your patterns into simple demand levels.

For example:

| Level | Description | Sales per hour (example) | Typical times |

|---|---|---|---|

| 1 | Quiet | £0–£150 | Mon–Thu 15:00–17:00 |

| 2 | Steady | £150–£400 | Tue–Thu 18:00–20:00 |

| 3 | Peak | £400+ | Fri–Sat 19:00–21:00 |

Then decide, for each level, what staffing you actually need. For instance, a Level 2 evening might need 1 manager, 2 servers, 1 runner, 2 kitchen, while a Level 3 peak might need 1 manager, 3 servers, 1 bartender, 2 runners, 3 kitchen.

These levels become the backbone of your staffing templates and rota templates. When you know what “Level 3 Friday night” looks like in both revenue and headcount, you can control labour cost instead of reacting in the moment.

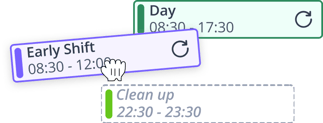

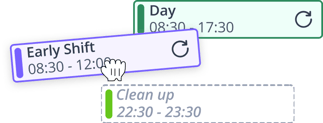

Step 4 – Turn your forecasts into smarter rotas

Now we translate demand levels into concrete shifts that keep service strong and labour costs under control.

Build staffing templates for slow, steady and peak trade

Your demand “levels” only become useful when they turn into a repeatable staffing template. Think roles, not names, so the rota template can be reused across weeks and sites.

Example templates:

Level 1 – quiet (e.g. Mon 15:00–17:00)

-

1 manager

-

1 server

-

1 chef

Level 2 – steady (e.g. Tue–Thu 18:00–20:00)

-

1 manager

-

2 servers

-

1 runner

-

2 kitchen

Level 3 – peak (e.g. Fri–Sat 19:00–21:00)

-

1 manager

-

3 servers

-

1 bartender

-

2 runners

-

3 kitchen

Keep one simple rota template per level and per area (restaurant, bar, delivery), then apply it whenever the forecast says “Level 2 Friday” or “Level 3 Saturday”. Flexible scheduling approaches like this are widely recommended in hospitality to match staffing to demand without constant fire-fighting.

Set labour cost and wage budget per shift in your rota

Once templates are in place, you decide how much each day or shift is allowed to cost. This is where you cut labour cost by 5–10% on purpose, not by accident.

A simple “budget backwards” approach:

- Start with sales forecast

Example: Friday forecast = £6,000. - Apply your target labour cost %

Target = 28% → labour budget for Friday = £6,000 × 0.28 = £1,680. - Translate that into hours

If your average wage (including NI/pension) is £12/hour, your budget is:

£1,680 ÷ £12 ≈ 140 hours total for the day. - Build the rota inside that budget

Spread 140 hours across roles and time bands. If you add more shifts, something else must come out.

Bake in minimum standards for service and fairness

A rota that “hits the numbers” but breaks your team will not last. Build a set of minimum standards into every staffing template to keep things fair and legal.

Best practices for a fair rota / fair scheduling approach:

-

Minimum headcount per area – never drop below a safe number on floor or line.

-

Skills mix rules – at least one person per shift able to close the bar, run the pass, or handle deliveries.

-

Max shift length – e.g. 9–10 hours max, with proper breaks.

-

Limits on split shifts and clopenings – avoid late-close + early-open combos unless truly necessary.

Step 5 – Run data-driven scheduling in real life

This is where you use the rota as a living tool, not a static spreadsheet pinned in the staff room.

Pre-shift: compare forecast vs actual and tweak the plan

A five-minute pre-shift huddle can save you hours of wasted labour. Use a simple three-step routine:

- Check – look at today’s bookings, weather and events vs your forecast.

- Adjust – move start times, shorten one or two quiet shifts, or reassign tasks (prep, cleaning, training).

- Communicate – explain the changes and what “good” looks like for the shift.

During the shift: redeploy, don’t just send people home

When trade is softer than expected, the default move is to send someone home early. That cuts hours, but it can also hit morale and future availability. A better approach is to redeploy and reduce wasted hours.

Practical ideas:

-

Move a server from floor to delivery packing or takeaway for an hour.

-

Shift a chef onto prep for tomorrow or batch cooking.

-

Bring forward deep-clean tasks, stock counts or training.

After the shift: 15-minute review to capture learnings

Finish each day or peak period with a short, repeatable review. Treat it as a weekly ritual rather than an occasional post-mortem.

Simple post-shift checklist:

-

Labour cost % vs target – did we hit the goal for today?

-

Sales per labour hour – did the team stay productive?

-

Guest feedback – reviews, complaints, compliments.

-

Staff feedback – which hours felt over or under-staffed?

Step 6 – Measure the impact of your 5–10% labour saving

Now you close the loop and prove that your changes are improving labour cost and overall restaurant performance.

The key metrics to track weekly and monthly

If you only track one or two numbers, you will miss what is really happening. The best KPIs to track labour cost in a UK restaurant are:

-

Labour cost % – staff costs as a percentage of turnover.

-

Sales per labour hour – total sales ÷ total hours worked.

-

Overtime hours – total overtime, by role and by person.

-

Staff turnover – starters vs leavers each month.

-

Guest satisfaction – reviews, NPS, complaints volume.

Track these weekly for quick course-corrections and monthly for bigger trends.

Frequently Asked Questions

-

Most independent UK restaurants aim for labour costs of around 25–30% of revenue, but many are now sitting slightly higher due to wage and tax increases. The “right” number depends on your concept and price point, so use it as a guide, not a rule. The key is measuring it weekly and spotting trends early, not chasing a perfect percentage.

-

Yes – if you focus on wasted hours, not people. Most savings come from better forecasting, smarter rotas, fewer last-minute changes, and less overtime. When you match staffing to true demand, you stop paying for dead time but keep enough people on to protect service and sales. Smart rostering tools and a simple weekly review can usually find that 5–10% over a few months.

-

You can absolutely start with spreadsheets and your POS reports. Many single-site operators begin by exporting sales, colour-coding busy vs quiet times, and building basic staffing templates. As you grow, rota and workforce management tools make life easier by forecasting demand and showing live labour costs as you schedule, which helps prevent drifting back into bad habits.

-

Weekly is ideal. A short review every week lets you compare labour % and sales per labour hour against your targets while fresh in everyone’s mind. Monthly reviews are still helpful, but they tend to be more “post-mortem”. A simple 15-minute weekly huddle with your supervisors is usually enough to tweak templates and stay on track.

-

Be honest about the pressure on labour costs but clear that you’re trying to protect jobs and hours. Involve the team in spotting wasted time, share simple targets, and celebrate when you hit them. Make sure changes improve fairness and reduce stressy peak shifts. If people see better planning and more predictable schedules, they’re much more likely to support it.