In this article we dive into what schedule optimization means for business operations and explore its benefits and challenges.

What is schedule optimization?

Schedule optimization in the context of business operations is a strategic approach to organizing and managing a company's tasks and resources.

This process aims to ensure that every part of the business schedule is arranged in the most effective way possible, leading to an optimized schedule. The goal is to find the optimal solution that maximizes efficiency and productivity while minimizing costs and downtime.

The components of an optimized schedule include:

- Task prioritization: Identifying the most important tasks and ensuring they are completed first.

- Resource allocation: Assigning the right amount of input resources, including workforce and materials, to the right tasks.

- Flexibility: Allowing some leeway in the schedule to accommodate unforeseen changes or emergencies.

Optimizing schedules involves a comprehensive scheduling process that incorporates various optimization methods, such as machine learning, mathematical programming, and constraint programming. These methods use historical data, decision variables, and objective functions to create a feasible solution for scheduling problems.

Without optimized scheduling, businesses can face several challenges:

-

Wasted resources: Misallocation of input resources, like time and labor, can lead to inefficiencies and increased costs.

-

Employee burnout: Overburdening employees with poorly planned schedules can result in stress and burnout, affecting employee morale and productivity.

-

Missed deadlines: Ineffective scheduling often leads to delays in project completion and missed deadlines, harming the business's reputation and client satisfaction.

By employing scheduling optimization techniques, businesses can overcome these challenges. Tools such as scheduling software and optimization models, including linear programming and machine learning algorithms, play a crucial role in this process.

These tools help in solving scheduling problems by providing a structured approach to workforce planning and optimization, ensuring that every task is assigned judiciously based on objective functions.

Moreover, optimization models facilitate better decision-making by analyzing various scenarios and predicting outcomes. This allows businesses to create optimized schedules that consider all relevant constraints and objectives, from workforce management to field service operations.

Schedule optimization in different industries

In various industries and management domains, schedule optimization plays a crucial role in ensuring smooth operations and maximizing output. Depending on the sector, the concept of scheduling may encompass different aspects, such as production planning, workforce planning, transportation planning, project workflow planning, and more.

1. Production planning:

In manufacturing industries, optimizing schedules is essential for coordinating production processes, allocating resources efficiently, and meeting demand. By employing scheduling tools and optimization models, businesses can streamline workflows, minimize idle time at work centers, and increase revenue by maximizing output.

2. Workforce planning:

For businesses with mobile workforces or staff schedules, workforce optimization is key. Rostering and distributing staff effectively ensure that the right skills are assigned to the right jobs at the right time. This not only enhances overall productivity but also improves employee retention and customer experience.

3. Transportation planning and routing:

In logistics and transportation sectors, schedule optimization involves planning and routing vehicles to meet delivery deadlines and optimize routes. By minimizing idle time and maximizing efficiency, businesses can save time and resources while improving the customer experience.

4. Project workflow planning:

In project-based industries like construction and IT services, scheduling tools help in planning project workflows, assigning jobs, and meeting due dates. Optimization models ensure that projects are completed on time and within budget, ultimately leading to increased revenue and customer satisfaction.

Regardless of the industry, the ultimate goal of schedule optimization remains the same: to maximize output, minimize idle time, and meet demand efficiently.

What is an optimization model?

Optimization models are powerful tools used in the realm of business scheduling to achieve the best possible outcomes. They provide a structured approach to optimizing schedules and improving business processes. Here's a step-by-step explanation of how optimization models work and their role in finding optimal solutions to scheduling problems:

How optimization models work?

Optimization models provide a systematic approach to solving scheduling problems by employing mathematical techniques to find the most efficient allocation of resources and tasks.

1. Problem formulation:

The first step in using an optimization model is to define the scheduling problem at hand. This involves identifying the objectives to be optimized, such as maximizing output or minimizing costs, and specifying any constraints that must be satisfied, such as resource limitations or due dates.

2. Objective function:

An objective function is a mathematical representation of the goal to be achieved. In the context of scheduling, the objective function defines the measure of success, such as maximizing productivity or minimizing idle time. Optimization models use this function to evaluate and compare different scheduling solutions.

3. Decision variables:

Decision variables represent the choices to be made in the scheduling process. These variables could include assigning tasks to workers, allocating resources to activities, or determining the sequence of operations. Optimization models use decision variables to generate feasible schedules that optimize the objective function.

4. Constraint programming:

Constraint programming is a key aspect of optimization models that ensures schedules meet all relevant constraints. Constraints could include factors such as resource availability, worker skills, and time constraints. Optimization models use constraint programming to generate schedules that satisfy these constraints while optimizing the objective function.

Role of objective functions

Objective functions play a crucial role in optimization models by defining the goal of the scheduling problem. They provide a clear measure of success, allowing businesses to prioritize objectives such as maximizing output or minimizing costs. By optimizing schedules based on the objective function, businesses can achieve the desired outcomes and improve overall efficiency.

What is constraint programming?

Constraint programming is a powerful technique used in schedule optimization to model and solve complex scheduling problems efficiently. Constraint programming involves representing a problem as a set of variables, each with a domain of possible values, and a set of constraints that define relationships between variables.

In the context of schedule optimization, constraint programming allows businesses to model scheduling problems by defining constraints such as resource availability, task dependencies, and time constraints. By solving these constraints, businesses can generate optimal schedules that meet all requirements and objectives.

How constraint programming helps solve complex scheduling problems?

Constraint programming provides a flexible and efficient framework for modeling and solving complex scheduling problems. It allows businesses to represent scheduling constraints in a natural and intuitive way, making it easier to define and solve intricate scheduling problems.

Constraint programming algorithms use various techniques, such as constraint propagation and search strategies, to efficiently explore the solution space and find feasible schedules that satisfy all constraints.

Examples of industries where constraint programming is commonly used

Constraint programming finds widespread application across various industries, revolutionizing scheduling and optimization processes to enhance efficiency and drive success.

1. Manufacturing:

In manufacturing industries, constraint programming is used to optimize production schedules, allocate resources such as machines and materials, and minimize production costs.

By modeling constraints such as machine capacities, material availability, and production deadlines, constraint programming helps businesses maximize output and meet customer demand efficiently.

2. Transportation and logistics:

In transportation and logistics sectors, constraint programming is used to optimize vehicle routing and scheduling, minimize transportation costs, and improve delivery efficiency.

By modeling constraints such as vehicle capacities, delivery time windows, and route restrictions, constraint programming helps businesses optimize routes, reduce fuel consumption, and enhance customer satisfaction.

3. Healthcare:

In healthcare settings, constraint programming is used to optimize staff scheduling, allocate resources such as hospital beds and operating rooms, and minimize patient waiting times.

By modeling constraints such as staff availability, patient priorities, and resource constraints, constraint programming helps healthcare facilities optimize resource utilization, improve patient outcomes, and enhance operational efficiency.

4. Project management:

In project-based industries such as construction and IT services, constraint programming is used to optimize project schedules, allocate resources such as manpower and equipment, and minimize project duration and costs.

By modeling constraints such as task dependencies, resource constraints, and project deadlines, constraint programming helps businesses optimize project workflows, meet project objectives, and deliver projects on time and within budget.

Incorporating machine learning in scheduling

Introducing machine learning into schedule optimization opens up new possibilities for businesses to improve efficiency and make more informed scheduling decisions.

Machine learning involves training algorithms to recognize patterns in data and make predictions or decisions based on those patterns.

In the context of schedule optimization, machine learning algorithms can analyze historical data, identify trends and correlations, and make predictions to improve scheduling decisions.

Analyzing data patterns and making predictions

Machine learning algorithms excel at analyzing large datasets and extracting valuable insights. By examining historical scheduling data, these algorithms can identify patterns such as peak demand times, resource utilization trends, and workflow bottlenecks.

With this information, businesses can make more accurate predictions about future scheduling needs and optimize their schedules accordingly.

Examples of incorporating machine learning in scheduling processes:

-

Predictive maintenance scheduling: Machine learning algorithms can analyze equipment performance data to predict when maintenance is likely to be needed. By scheduling maintenance tasks proactively, businesses can minimize downtime and avoid costly repairs.

-

Demand forecasting: Machine learning algorithms can analyze sales data and market trends to forecast future demand for products or services. By incorporating these forecasts into scheduling decisions, businesses can adjust staffing levels and production schedules to meet anticipated demand.

-

Dynamic pricing and resource allocation: Machine learning algorithms can analyze real-time data on customer behavior and market conditions to adjust pricing and allocate resources dynamically. For example, in the transportation industry, algorithms can optimize routes and adjust fares based on factors such as traffic congestion and demand fluctuations.

-

Employee scheduling and shift planning: Machine learning algorithms can analyze employee availability, skills, and preferences to generate optimized shift schedules. By considering factors such as employee fatigue, workload distribution, and skill requirements, businesses can create schedules that improve employee satisfaction and productivity.

What is mathematical optimization?

Mathematical optimization is a fundamental approach used in schedule optimization to find the most efficient allocation of resources and tasks. Mathematical optimization involves formulating a mathematical model that represents the scheduling problem and applying optimization techniques to find the best possible solution.

In the context of schedule optimization, mathematical optimization aims to maximize productivity, minimize costs, or achieve other specified objectives while satisfying constraints such as resource limitations, time constraints, and task dependencies.

How do mathematical optimization techniques help find optimal solutions to scheduling problems?

One common mathematical optimization technique used in schedule optimization is linear programming. Linear programming involves optimizing a linear objective function subject to linear constraints.

Linear programming can be used to allocate resources such as manpower, machines, and materials to tasks in a way that maximizes productivity or minimizes costs while satisfying constraints such as resource availability and task dependencies.

Applications of mathematical optimization in different business scenarios

Applications of mathematical optimization in different business scenarios showcase its versatility and effectiveness in solving complex problems to optimize resources and achieve organizational objectives.

1. Production planning:

In manufacturing industries, mathematical optimization techniques are used to optimize production schedules, allocate resources such as machines and materials, and minimize production costs.

By formulating production scheduling problems as mathematical optimization models, businesses can maximize output and minimize costs while satisfying constraints such as machine capacities, material availability, and production deadlines.

2. Inventory management:

In retail and supply chain management, mathematical optimization techniques are used to optimize inventory levels, minimize holding costs, and maximize service levels.

By formulating inventory management problems as mathematical optimization models, businesses can determine the optimal order quantities, reorder points, and stocking policies that minimize inventory costs while ensuring sufficient stock availability to meet customer demand.

3. Transportation and logistics:

In transportation and logistics sectors, mathematical optimization techniques are used to optimize vehicle routing and scheduling, minimize transportation costs, and improve delivery efficiency.

By formulating vehicle routing and scheduling problems as mathematical optimization models, businesses can optimize routes, reduce fuel consumption, and enhance customer satisfaction while satisfying constraints such as vehicle capacities, delivery time windows, and route restrictions.

4. Project management:

In project-based industries such as construction and IT services, mathematical optimization techniques are used to optimize project schedules, allocate resources such as manpower and equipment, and minimize project duration and costs.

By formulating project scheduling problems as mathematical optimization models, businesses can optimize project workflows, meet project objectives, and deliver projects on time and within budget while satisfying constraints such as task dependencies, resource constraints, and project deadlines.

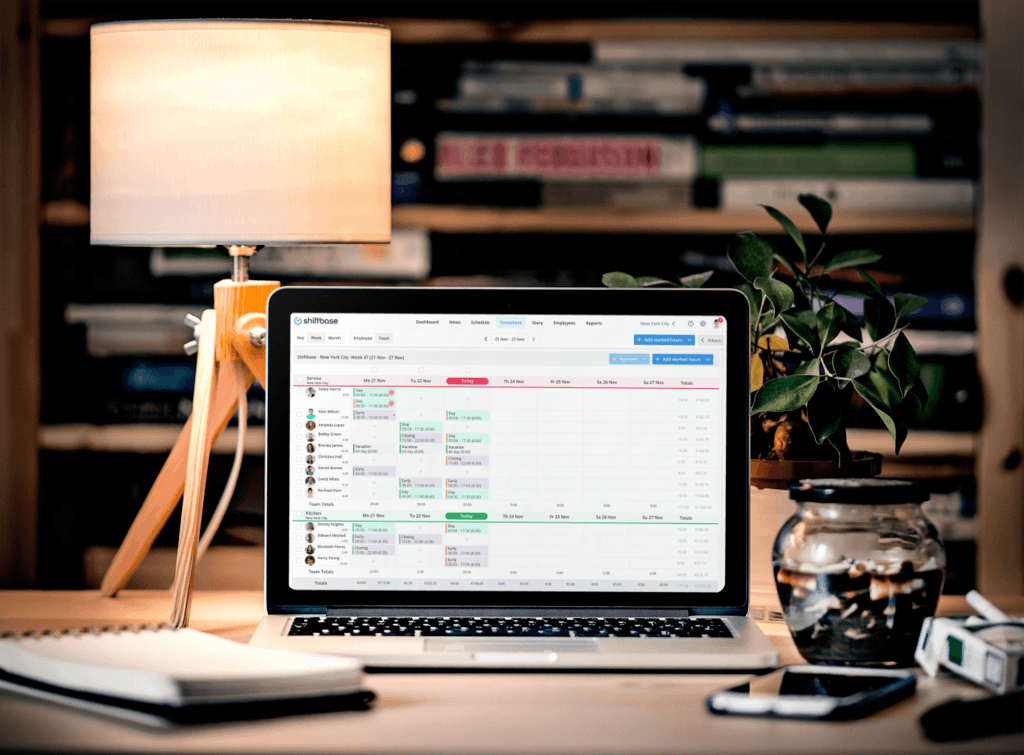

Quick and easy way for schedule optimization: Scheduling tools

Shiftbase is a comprehensive workforce management software that simplifies the scheduling process for businesses of all sizes. It offers a user-friendly interface and powerful features to help businesses optimize their workforce scheduling efficiently.

Key features of shiftbase:

-

Employee scheduling: Shiftbase allows businesses to create and manage employee schedules effortlessly. With intuitive drag-and-drop functionality, managers can easily assign shifts, set recurring schedules, and adjust staffing levels to meet demand.

-

Time tracking: Shiftbase provides robust time tracking capabilities, allowing employees to clock in and out electronically. Managers can monitor employee hours in real-time, track overtime, and ensure compliance with labor regulations.

-

Absence management: Shiftbase simplifies absence management by allowing employees to request time off directly through the software. Managers can review and approve requests, track employee absences, and maintain accurate attendance records.

Shiftbase - Workforce management software streamlines the scheduling process, improves workforce efficiency, and enhances overall productivity for businesses across various industries.

Achieve schedule optimization with Shiftbase

Navigating the complexities of schedule optimization is a key factor in successful business operations, and Shiftbase is an invaluable tool in this process.

Through its advanced employee scheduling capabilities, Shiftbase enables businesses to efficiently manage work schedules, ensuring maximum productivity while balancing employee preferences.

Additionally, the time tracking feature offers real-time insights into workforce allocation, further aiding in optimization. The integrated absence management system also plays a crucial role in maintaining operational continuity.

To transform your scheduling strategy and enhance operational efficiency, try Shiftbase free for 14 days by signing up here. Experience the benefits of optimized scheduling with Shiftbase.